Blog

CNC Robodrill Machine Tending Automation Cell: Revolutionizing Manufacturing with Precision and Efficiency

The Future of Manufacturing with CNC Robodrill Machine Tending Automation Cell

The manufacturing industry has witnessed rapid technological advancements in recent years, with automation playing a significant role in transforming production processes. One of the most notable innovations is the CNC Robodrill Machine Tending Automation Cell, which is designed to enhance efficiency, precision, and productivity on the factory floor. This cutting-edge solution is enabling manufacturers to reduce labor costs, minimize downtime, and maximize output. In this article, we will delve into the features, benefits, and applications of CNC Robodrill Machine Tending Automation Cell and explore how it is revolutionizing manufacturing operations.

What is CNC Robodrill Machine Tending Automation Cell?

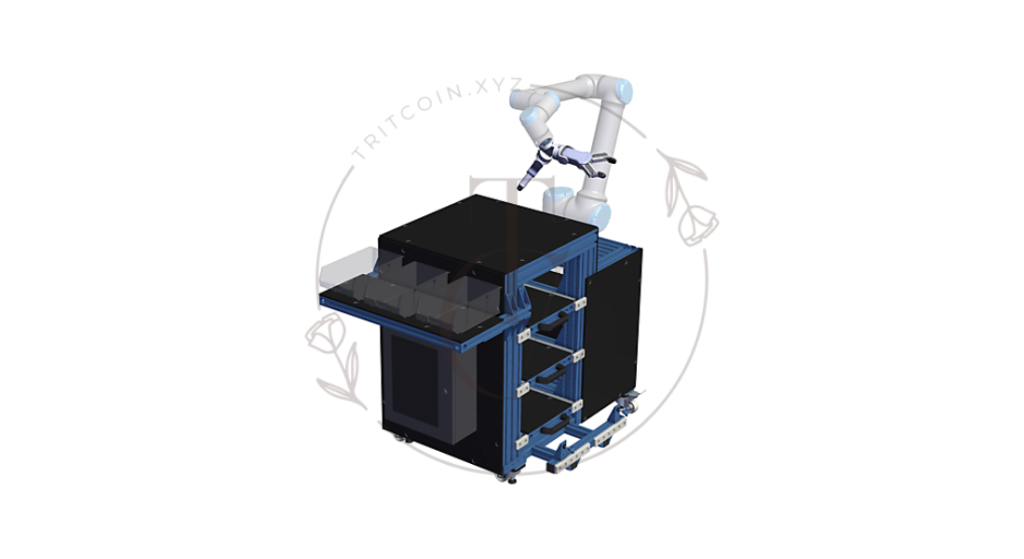

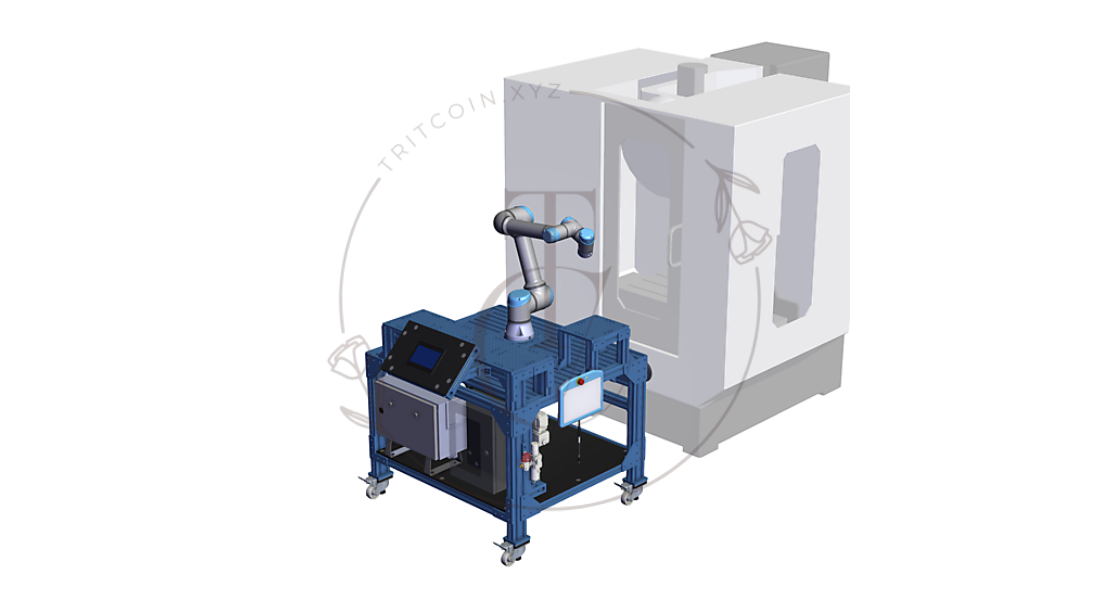

A CNC Robodrill Machine Tending Automation Cell is an advanced robotic system designed to automate the loading and unloading of workpieces in CNC machines, specifically Robodrill machines. These machines are typically used for precision drilling, milling, and tapping operations in the manufacturing of parts for various industries, including automotive, aerospace, and electronics.

The Robodrill Machine Tending Automation Cell consists of a robotic arm or automated system that works seamlessly with the CNC machine. It is programmed to load raw materials into the CNC machine and unload finished products, all while maintaining high levels of accuracy and speed. This automation system improves production efficiency by minimizing manual labor and reducing the risk of human error.

Key Features of CNC Robodrill Machine Tending Automation Cell

1. Robotic Arm Integration

The CNC Robodrill Machine Tending Automation Cell utilizes a robotic arm to automate the process of loading and unloading workpieces into the CNC machine. The robotic arm is equipped with advanced sensors and precise movement capabilities, allowing it to handle delicate components with ease. This integration enables the system to operate autonomously, significantly reducing the need for human intervention and minimizing the risk of errors.

2. High-Speed Operation

The CNC Robodrill Machine Tending Automation Cell is designed for high-speed operations, ensuring that parts are loaded and unloaded quickly. This results in reduced cycle times and improved throughput, allowing manufacturers to increase their production output. The high-speed nature of the automation system also helps maintain consistent product quality, as the system can perform repetitive tasks without fatigue.

3. Advanced Software Control

The operation of the CNC Robodrill Machine Tending Automation Cell is controlled by advanced software that coordinates the robotic arm’s movements, as well as the CNC machine’s operations. This software ensures precise control over the loading and unloading processes, enhancing the system’s accuracy and reliability. It also allows manufacturers to customize the automation cell for specific production needs, optimizing workflows and minimizing inefficiencies.

4. Flexible Workpiece Handling

The CNC Robodrill Machine Tending Automation Cell is designed to handle a variety of workpieces, from small and intricate parts to larger components. The system can be equipped with interchangeable grippers and fixtures, allowing it to adapt to different types of parts. This flexibility makes it an ideal solution for industries with diverse production requirements, including those with complex or customized parts.

5. Safety and Reliability

Safety is a top priority in any manufacturing environment, and the CNC Robodrill Machine Tending Automation Cell is equipped with numerous safety features to protect both the machine and the operator. These features include emergency stop buttons, safety barriers, and sensors that prevent collisions between the robotic arm and other equipment. The system is also designed for reliability, with built-in redundancies to ensure continuous operation and minimize the risk of downtime.

Benefits of CNC Robodrill Machine Tending Automation Cell

1. Increased Productivity

The primary benefit of implementing a CNC Robodrill Machine Tending Automation Cell is the significant boost in productivity. By automating the loading and unloading process, manufacturers can achieve faster cycle times, allowing for more parts to be produced in less time. The high-speed operation of the robotic arm ensures that the system can maintain consistent performance throughout long production runs, leading to higher throughput and greater overall efficiency.

2. Reduced Labor Costs

Labor costs are a significant expense in manufacturing, and CNC Robodrill Machine Tending Automation Cell helps mitigate these costs by reducing the need for manual labor. With the automation system handling the loading and unloading tasks, manufacturers can reduce the number of operators required to oversee the production process. This not only helps lower labor costs but also allows workers to focus on more value-added tasks, such as quality control and process optimization.

3. Enhanced Precision and Consistency

Precision is crucial in manufacturing, especially when producing components that require tight tolerances. The CNC Robodrill Machine Tending Automation Cell ensures that parts are loaded and unloaded with high accuracy, reducing the potential for human error. The system’s advanced software and robotic arm integration allow for consistent handling of workpieces, ensuring that each part is produced to the same high standard, no matter how many units are produced.

4. Improved Safety

By automating the loading and unloading process, the CNC Robodrill Machine Tending Automation Cell minimizes the need for human operators to interact directly with the machine. This reduces the risk of accidents and injuries, particularly in environments where heavy or hazardous materials are being handled. The system’s safety features, such as sensors and emergency stop buttons, further enhance workplace safety, ensuring that operators and equipment remain protected at all times.

5. Lower Downtime and Maintenance Costs

The CNC Robodrill Machine Tending Automation Cell is designed for reliability and minimal maintenance. The system is built with high-quality components that are engineered to withstand the rigors of continuous operation. With regular maintenance, the system can operate at peak performance for extended periods, minimizing downtime and reducing the need for costly repairs. Additionally, the automation cell’s efficiency helps prevent delays caused by manual errors or operator fatigue.

Applications of CNC Robodrill Machine Tending Automation Cell

1. Automotive Industry

The automotive industry is one of the largest sectors benefiting from CNC Robodrill Machine Tending Automation Cells. These systems are used to automate the manufacturing of components such as engine parts, transmission systems, and chassis components. By increasing the speed and precision of production, manufacturers can meet the high demand for automotive parts while maintaining strict quality standards.

2. Aerospace Industry

The aerospace industry requires highly precise components that meet rigorous safety standards. CNC Robodrill Machine Tending Automation Cells play a crucial role in automating the production of complex parts, such as turbine blades, engine components, and landing gear. The system’s ability to handle delicate and intricate parts with high accuracy makes it an essential tool for the aerospace sector.

3. Electronics Manufacturing

In the electronics manufacturing industry, CNC Robodrill Machine Tending Automation Cells are used to produce components such as circuit boards, connectors, and housings. These parts often require precise drilling, milling, and tapping operations, making the automation cell an ideal solution for reducing cycle times and improving product quality.

4. Medical Device Manufacturing

The medical device industry demands high levels of precision and cleanliness in the production of components like implants, surgical instruments, and diagnostic devices. CNC Robodrill Machine Tending Automation Cells provide a reliable and efficient solution for producing these critical parts with the necessary precision and consistency.

Maintenance and Care for CNC Robodrill Machine Tending Automation Cell

Regular maintenance is essential to ensure the optimal performance and longevity of the CNC Robodrill Machine Tending Automation Cell. Routine tasks include checking the robotic arm for wear and tear, inspecting sensors for proper functionality, and cleaning the CNC machine’s components. Additionally, manufacturers should conduct periodic software updates to ensure that the automation system remains compatible with new technologies and production requirements.

Conclusion: Embracing the Future of Manufacturing with CNC Robodrill Machine Tending Automation Cell

The CNC Robodrill Machine Tending Automation Cell represents a major leap forward in manufacturing automation. By integrating advanced robotic systems with precision CNC machines, manufacturers can achieve higher productivity, lower labor costs, and improved precision. Whether in the automotive, aerospace, electronics, or medical device sectors, this innovative solution is revolutionizing the way parts are produced and assembled.

With its ability to handle a wide variety of workpieces, enhance safety, and reduce downtime, the CNC Robodrill Machine Tending Automation Cell is an invaluable tool for any manufacturer looking to stay competitive in an increasingly automated world. Investing in this technology not only boosts operational efficiency but also positions manufacturers to meet the growing demands of modern production.